Our Representations

- Müller Martini

- ROBATECH

- Hunkeler

- RIMA System

- STRAPEX

- Multigraf

- Schober

- WH Leary

- SITMA

- Solema

- Harouf

- DDD

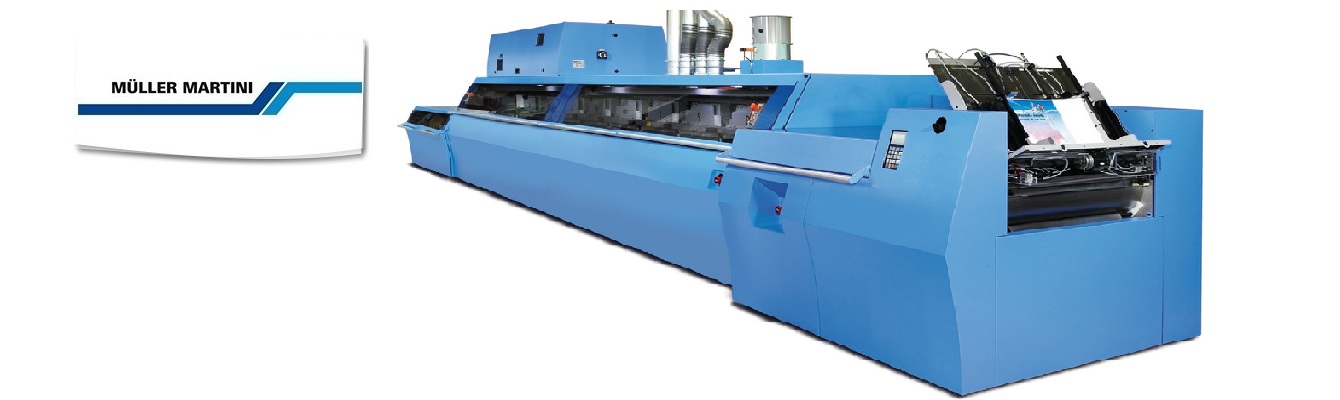

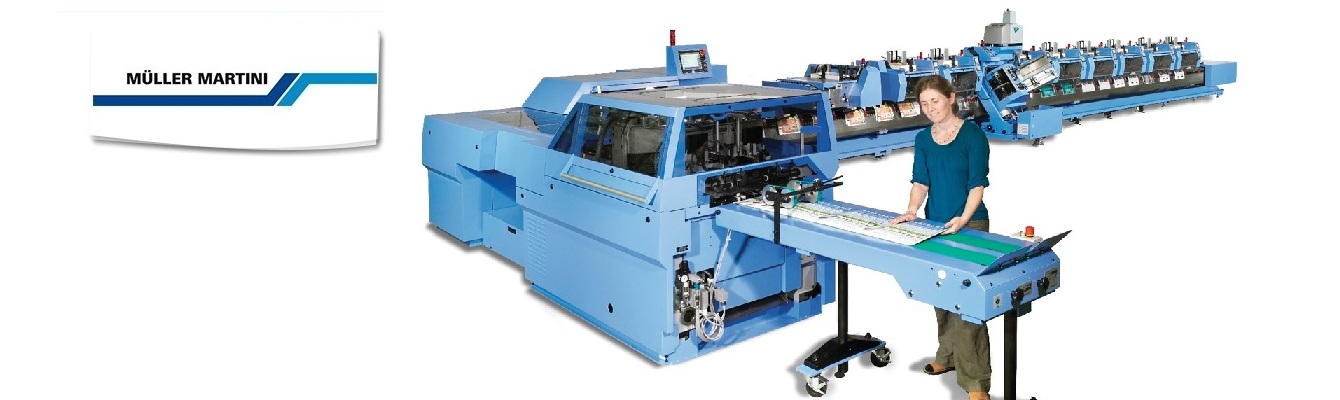

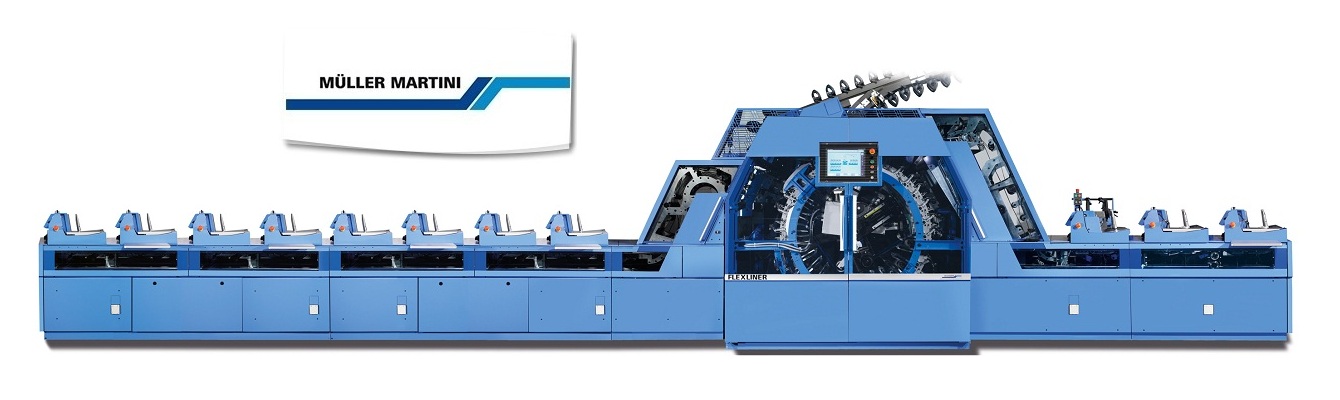

Their systems are developed and manufactured in ultramodern production facilities in Switzerland, Germany, and the USA.

As the cost and time pressures in the printing industry continue to grow, there is also a demand for the quality of the end products to improve and the diversity of the products to be expanded. Finding the right answer requires extensive know-how of the processes of manufacturing printed products as well as technical competence when it comes to designing solutions.

These are the strengths of Muller Martini. With flexible, cost-effective and fully-integrated first-class technology along with services portfolio, MMServices, Muller Martini customers can successfully meet the challenges of today and tomorrow.

Muller Martini’s extensive product and service offering ranges from variable-size web-offset printing presses, saddle stitchers, perfect binders, hardcover systems, and newspaper mailroom systems to state-of-the-art technology for manufacturing digitally printed products in saddle stitching, perfect binding or hardcover production.

With Muller Martini, you can rely on our over 60 years of quality, experience and expertise for innovative solutions in the graphic design industry.

Robatech precise and efficient systems support customers to manufacture their products more economically.

International activities are coordinated from headquarter in Muri, Switzerland, with nearly 150 dedicated and highly trained professionals in the areas of development, procurement, manufacturing, marketing, sales, service and administration.

Robatech is a global, private company specializing in innovative, high–quality adhesive application equipment. In over 60 countries, experts advise clients on all matters relating to adhesive application, with quick and comprehensive support. Spare parts are available locally. The parts are quickly and easily replaced due to high modularity and the ability to re–use parts in many devices.

All Robatech products are designed sustainably. They conserve energy and resources, and have a long life span. Operators appreciate the user friendly interface and advanced mechanisms that protect them whilst using the devices. Robatech products make your production processes more efficient and safer.

Robatech is your partner for environmentally and user–friendly application of adhesives.

Over 25 years of experience in waste management systems, Hunkeler is a leading Swiss supplier of compactors, shredders, and customizable systems, to ensure waste in paper, cardboard and poly wraps processes is efficiently disposed of. By using compact units or complete systems specific to customers’ needs, an increase production efficiency is assured.

Hunkeler realize solutions for the disposal logistic for recyclables like paper, cardboard, foils, PET, wood, waste, etc. to guarantee an efficient management of the waste. From compact solutions directly at the collection point to integrated system solutions to support the production process.

Hunkeler realize solutions for the disposal logistic for recyclables like paper, cardboard, foils, PET, wood, waste, etc. to guarantee an efficient management of the waste. From compact solutions directly at the collection point to integrated system solutions to support the production process.

With an impressive references list from successful installations around the world, in various fields such as recycling, pharma, metal, beverage, construction, chemical, printing, and packing industries, a solution for your project is available; from consulting, through planning, and final setting in operation, plus support, is only one stop away at Hunkeler.

Established in 1970, and specialized in press-delivery-systems, such as conveyers, stackers, rotary trimmers, palletizers, and various solutions for the post-press field, RIMA are a worldwide leader with numerous references in both commercial and converting industries.

Heavy-Duty equipment designed and built between their group of factories in the U.S. and Germany, they offer high quality, flawless, durable and reliable equipment to customers. RIMA working environment is conducive to excellence. Their team of experts are motivated, competent with international references and experience.

Heavy-Duty equipment designed and built between their group of factories in the U.S. and Germany, they offer high quality, flawless, durable and reliable equipment to customers. RIMA working environment is conducive to excellence. Their team of experts are motivated, competent with international references and experience.

Your project is in safe hands: Consulting, Solution Design, Manufacturing, Pre-Acceptance, Installation, Start-Up, Production Control, Lifetime Support – together with the customer, they develop customized solutions and configurations which are optimized on the individual product portfolio. Through all project phases RIMA will be your reliable partner.

Latest technology in equipment combined with highest quality standards [EN-ISO 9001] and half a century of experience will grant you maximum availability and security. Strapex offers you tailor-made solutions for your individual application.

Strapex serves the market with system solutions and services for product securing during transportation, for production, trade, and logistics. Our strapping applications cover product securing during transportation, bundled products and shipping boxes, printed matter, protection (pilferage), to support the supply chains of various industries.

The motto “We Create New Solutions” is heavily backed by Eurofold concept machines at Multigraf AG company in Muri, Switzerland. Thanks to the great variety of machines in the Print-Finishing field many possibilities for post-print processing is now flexible and cost effective; be it for automatic envelope feeding, digital or commercially printed products for folding, cutting, creasing, or perforating.

High speed solutions for feeding and stacking sheets are available. Also, in designing the Eurofold folding machines, the idea of “modular” is being further advanced. All models can be supplied with standard, manual folding plates and with simple basic equipment. If the requirements of the user change, the machines can be upgraded to the new features at any time.

High speed solutions for feeding and stacking sheets are available. Also, in designing the Eurofold folding machines, the idea of “modular” is being further advanced. All models can be supplied with standard, manual folding plates and with simple basic equipment. If the requirements of the user change, the machines can be upgraded to the new features at any time.

Multigraf, a successful Swiss supplier since 30 years, of high quality finishing machines, for your commercial and digitally printed products industry.

Since more than 60 years ago, Schober was founded in Stuttgart, Germany, specializes in the development, design and manufacturing of rotary tools, modules and specialty machines widely used in film, foil, packaging, non-wovens and paper converting industries. These technically superior equipment are sold in more than 100 countries worldwide.

Reasons which speak for Schobertechnologies are innovative products due to in-house Research and Development departments, Quality Assurance of all product, ISO 9001:2008 certification, Expert advise and consultation regarding integration of high performance modules and tools into new and existing production machines, and an extensive Worldwide after-sales-service.

Reasons which speak for Schobertechnologies are innovative products due to in-house Research and Development departments, Quality Assurance of all product, ISO 9001:2008 certification, Expert advise and consultation regarding integration of high performance modules and tools into new and existing production machines, and an extensive Worldwide after-sales-service.

Customized solutions available for your needs in Rotary punching tools. High end rotary cutting, scoring, embossing and perforating tools, Ultrasonic sealing and welding tools, Laser cutting and perforating systems, Hologram hot sealing and hot foil embossing modules, and Machines to cut, punch, score, and emboss a variety of materials, and many more …

With Schober, quality products ensure a high level of production uptime and effectively reduce production costs.